Energy Generation and Storage

Energy Generation and Storage

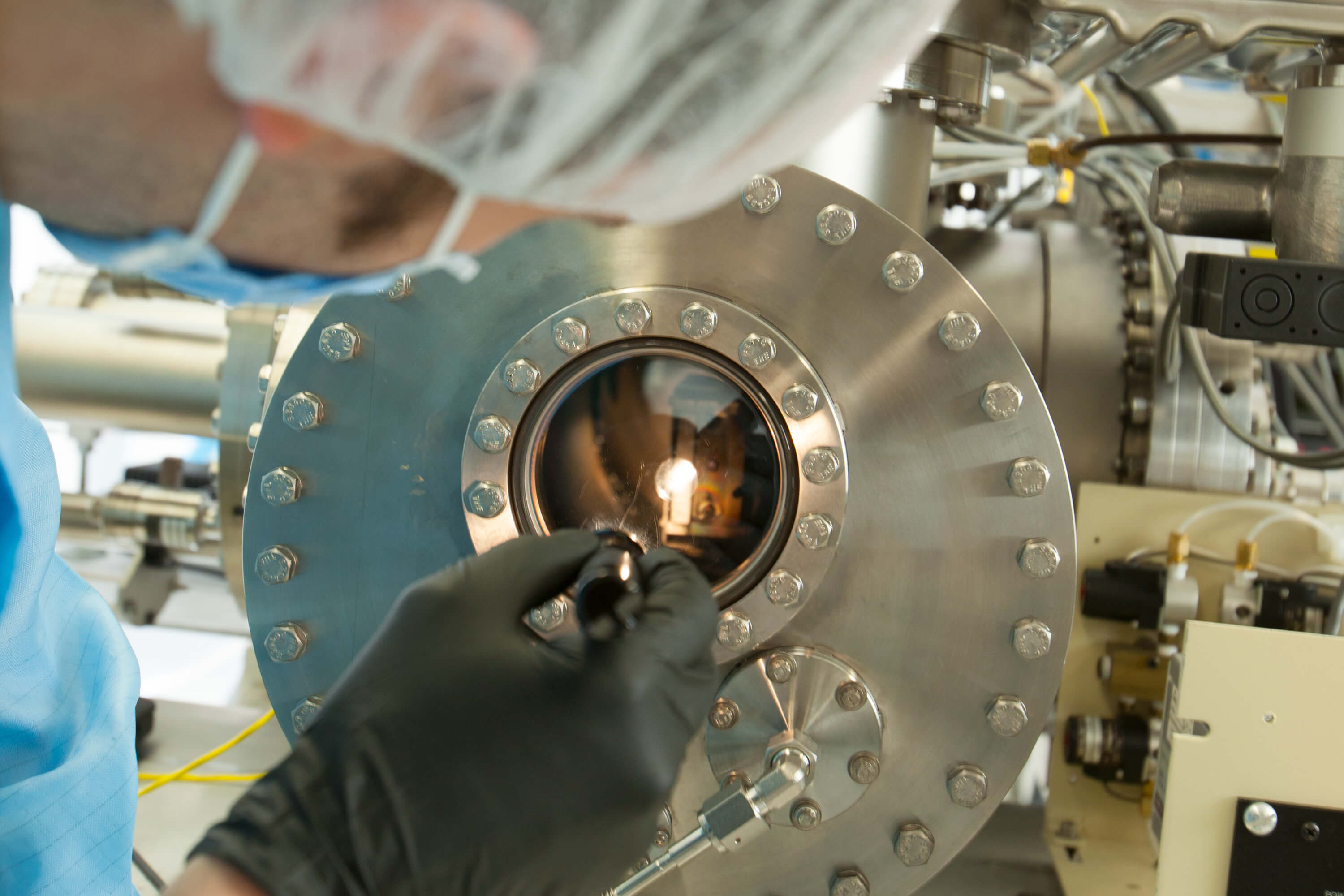

From battery breakthroughs to future fuels, ONAMI’s portfolio companies include leading technologies with significant potential. Some already have successful products in the marketplace. Others are advancing their inventions in the lab. Still others are actively seeking investors and/or commercial partners.

If you’re an inventor, you might find technologies like yours. If you’re an investor, you can be assured these companies have been thoroughly vetted by the ONAMI Team. Contact us if you have questions.

Crystal Clear Technologies

NWUAV

Pacific Light Technologies

March 5 – April 9

March 5 – April 9 Register now.

Register now.